Fabric Face-Off: Picking the Perfect Boat Cover Material

Why Choosing the Right Boat Cover Material Matters

Choosing the right boat cover materials is the first line of defense for your vessel. The wrong material can lead to mold, UV damage, and costly repairs, while the right one protects your yacht's interior and maintains its value.

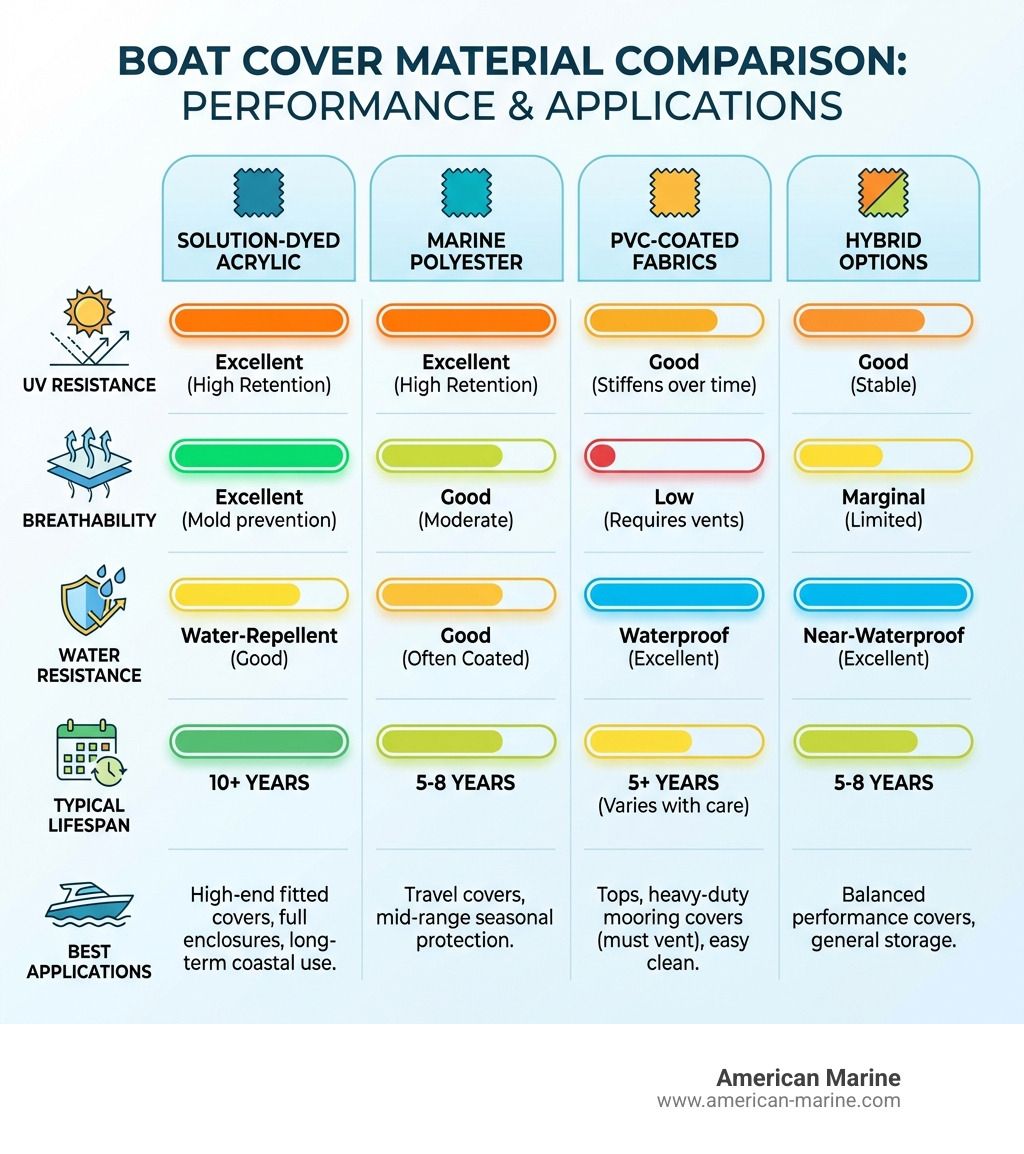

Quick Answer: Top Boat Cover Materials

- Solution-Dyed Acrylic (Sunbrella®, Outdura®) - Best for UV resistance and longevity (10+ years); highly breathable.

- Marine-Grade Polyester (Sun-DURA®, Top Notch®) - Strong and stable, lasts 5-8 years, more affordable than acrylic.

- PVC/Vinyl-Coated Fabrics (Stamoid™, Weblon®) - 100% waterproof and easy to clean, but requires ventilation.

- Hybrid Coated Options (Top Gun®, Odyssey®) - Near-waterproof with some breathability for balanced performance.

Key factors to consider:

- UV Resistance - Critical for coastal/offshore use

- Breathability - Prevents mold and mildew under the cover

- Chafe Resistance - Important for frequent covering/uncovering

- Water Repellency - Balance between protection and moisture escape

- Fabric Weight - Lighter (5-8 oz) for frequent use, heavier (9+ oz) for storage

A quality boat cover can last 5-10 years. Sunbrella® and Sattler® acrylics retain strength for up to 10 years in harsh UV, while polyesters typically last 5-8 years.

As one forum contributor noted, "Acrylic canvas is probably the dominant type of material" for fitted covers, while PVC is popular for its ease of maintenance—"when it goes green you can easily wash it."

Breathability is crucial. A manufacturer warns: "Waterproof materials do not allow interior moisture to escape which promotes the growth of mold and mildew..." This is vital for luxury vessels where interiors represent significant value.

I'm Jeremy Bottau, owner of American Marine. We specialize in custom marine canvas for luxury yachts in South Florida, using 3D patterning and elite boat cover materials for precision-crafted protection. I've learned that the right material is the foundation of a successful custom cover.

Core Boat Cover Materials: A Head-to-Head Comparison

Choosing the right boat cover materials is critical for your vessel's longevity, especially in South Florida's sun and humidity. The main material categories are acrylic canvas, coated polyester, and PVC/vinyl fabrics, each with unique strengths for custom marine covers.

Let's explore the specifics of these marine canvas material options.

The Great Debate: Polyester vs. Solution-Dyed Acrylic

The classic debate in boat cover materials is polyester versus acrylic. Both are popular but excel in different areas regarding strength, longevity, and UV resistance.

Polyester fabrics like Sun-DURA™ (a 600 denier, solution-dyed polyester) or Top Notch® are known for initial strength and stability, with warranties of 7-8 years. However, polyester loses significant strength within five years of UV exposure. While robust when new, its long-term durability in high-UV environments like Miami and Fort Lauderdale can be a concern.

Solution-dyed acrylic fabrics like Sunbrella® and Sattler® Marine Grade are the champions of longevity and UV resistance. These premium boat cover materials retain strength for up to 10 years under intense UV, backed by warranties like Sunbrella's 10-year limited warranty. Their solution-dyed nature ensures superior colorfastness. While excellent against UV, acrylic isn't as chafe resistant as some polyesters, so high-friction areas may need reinforcement patches.

In short, choose solution-dyed acrylic for maximum longevity and UV resistance. Choose marine-grade polyester for a balance of initial strength, stability, and affordability, accepting its shorter lifespan.

We often recommend exploring options like Sauleda Acrylic Canvas for its proven performance in marine environments.

Understanding Vinyl and PVC-Coated Fabrics

PVC-coated fabrics like Stamoid™ and Weblon Regatta® offer a different set of properties for boat cover materials, as they are inherently waterproof.

The main advantage of PVC-coated fabrics is their waterproofing capability, creating an impenetrable barrier to moisture. This non-porous surface also makes them easy to clean. As one user noted, when they "go green" from grime, you can simply wipe them clean, unlike canvas finishes.

However, the trade-off for waterproofing is a lack of breathability. Non-breathable PVC fabrics trap moisture from condensation or humidity, creating a breeding ground for mold and mildew that can damage interiors and electronics. Therefore, proper ventilation is crucial when using these materials.

Regarding durability and weight, PVC-coated fabrics are heavier (e.g., 14 oz) than most acrylics or polyesters. This weight adds robustness and reduces flapping but makes them more cumbersome. They often carry a 5-year warranty.

PVC-coated vinyl is excellent for bimini tops where waterproofness and easy cleaning are key. For full boat covers in humid South Florida, however, ventilation is critical to prevent mold. Learn more in our post on Waterproof Marine Vinyl Fabric.

Key Performance Factors: What Really Matters for Protection?

When selecting boat cover materials, performance is as important as composition. Key factors like water resistance, UV protection, and durability are crucial for protecting your vessel in the demanding South Florida environment.

A fabric's inherent properties and any applied coatings determine its durability and ability to withstand the elements.

Waterproof vs. Water-Resistant: A Crucial Distinction

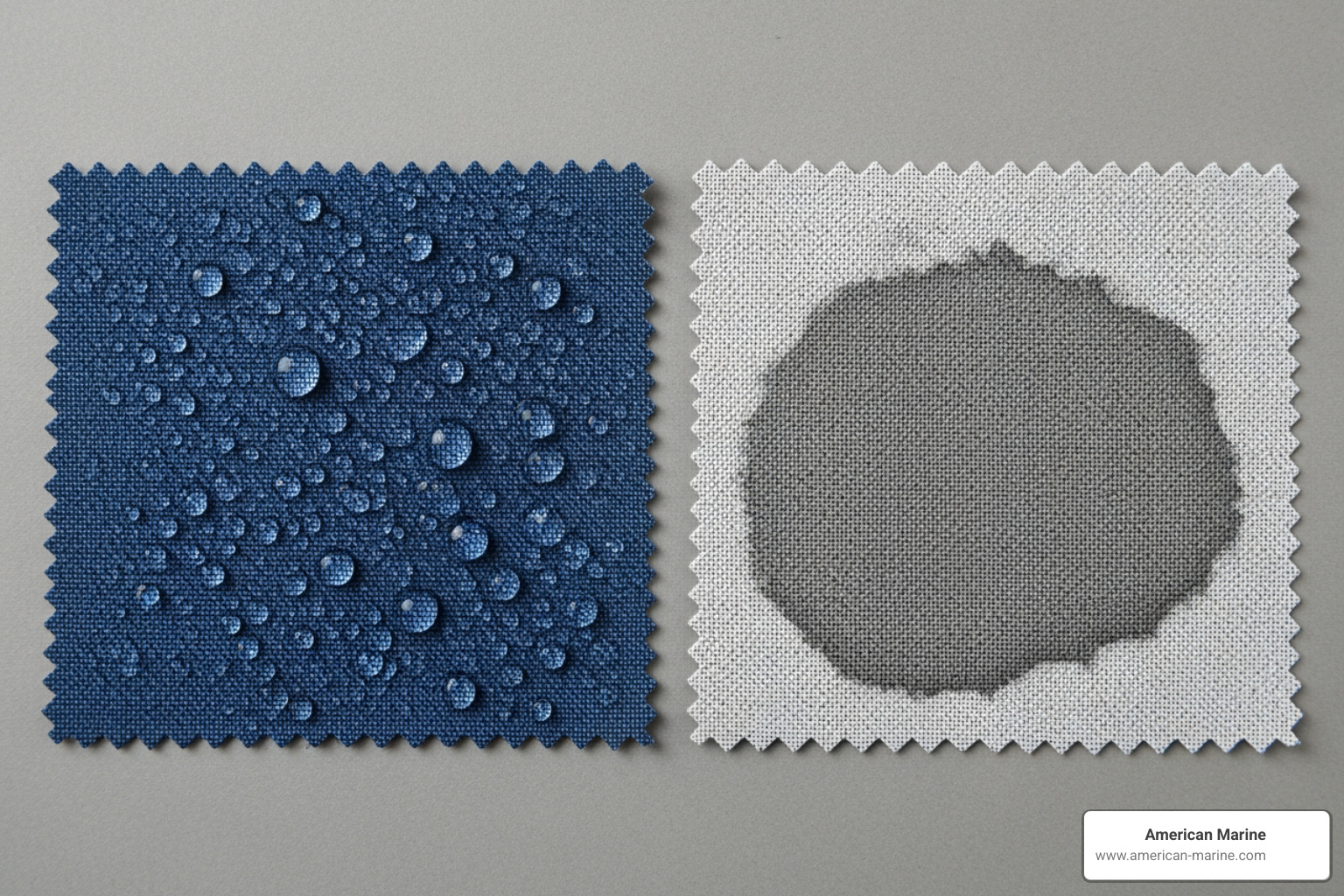

The terms "waterproof" and "water-resistant" are often confused, but for boat cover materials, the difference is critical for your boat's health.

Waterproof fabrics (like vinyl-coated Stamoid™ or Weblon Regatta®) completely block water. The major drawback is that they are non-breathable, trapping moisture and leading to mold and mildew. This is a critical concern for luxury yachts with sensitive interiors and electronics. If you choose a waterproof material, proper ventilation is non-negotiable.

Water-resistant fabrics (like acrylic Sunbrella® or polyester Sun-DURA™) shed water while allowing air to circulate. Their repellency comes from a coating that may need reapplication (e.g., 303® Fabric Guard) every few years. The key advantage is breathability, which allows moisture to escape and significantly reduces the risk of mold and mildew, protecting your boat's interior.

For wooden boats, breathability is paramount. Wood needs to "breathe" to prevent rot from trapped moisture. A non-breathable cover creates a humid microclimate that accelerates rot. We almost exclusively recommend breathable, water-resistant fabrics for wooden boats, even if the wood is epoxied.

Fabric coatings and treatments improve performance by adding water repellency, UV inhibitors, and mildew resistance. These coatings degrade over time from sun and cleaning, so periodic re-treatment is necessary to maintain optimal performance.

Balancing UV, Chafe, and Tear Resistance

In South Florida, balancing UV, chafe, and tear resistance is a critical factor in selecting boat cover materials.

UV resistance is the top priority in South Florida's coastal environments. The intense sun in Miami and Fort Lauderdale rapidly degrades fabrics. Solution-dyed acrylics like Sunbrella® offer superior UV resistance, holding their strength for up to 10 years, making them essential for long-term protection.

Chafe resistance is a fabric's ability to withstand abrasion from contact with cleats, stanchions, or straps. It prevents localized wear that can cause holes. While excellent against UV, acrylics are less chafe-resistant than some polyesters. We recommend reinforcement patches (e.g., from robust vinyl like Shelter-Rite®) in high-wear areas.

Tear resistance is the fabric's ability to stop a small cut from becoming a large tear. Heavier, higher-denier fabrics generally offer better tear resistance.

When to prioritize each:

- UV resistance: Always prioritize for boats in South Florida's constant sun to prevent fabric breakdown.

- Chafe resistance: Prioritize for high-contact areas, frequent use, or trailering to prevent localized damage.

- Tear resistance: Prioritize for covers that face rough handling or potential snagging.

We aim for balance. We select primary boat cover materials for their UV resistance and then strategically reinforce high-chafe areas to create a durable, long-lasting cover.

Practical Considerations for Your Boat Cover Fabric

Practical factors like climate, boat usage, and aesthetics are also key when selecting boat cover materials. In South Florida, these factors are amplified by our unique weather and boating lifestyles.

Fabric Weight and Denier Explained

A fabric's weight and denier are crucial indicators of its strength and suitability for different cover types.

Fabric weight, measured in ounces per square yard (oz/sq yd), often correlates with durability.

- Lighter fabrics (5-8 oz) are easier to handle, making them good for mooring covers or frequent use. Poly-Flex II, a 5.3 oz polyester, is a good example, offering decent durability for its weight.

- Heavier fabrics (9+ oz) are ideal for long-term storage and maximum protection. Sunbrella® Acrylic (9.25 oz) is a prime example, offering superior protection and less flapping in high winds.

Denier (D) indicates the thickness and density of the threads in a fabric. A higher denier means a stronger, more robust fabric. For example, Sun-DURA™ is a 600 denier (600D) polyester, signifying a strong weave. Considering both weight and denier gives a full picture of a material's strength.

We consider the cover's intended use. A frequently used boat may benefit from a lighter material for easier handling, while a yacht in long-term storage requires a heavy-duty fabric for maximum protection.

The Importance of Colorfastness and Solution-Dyed Fabrics

In sunny South Florida, colorfastness is a key indicator of quality for boat cover materials. A faded cover detracts from a yacht's appearance and signals UV degradation.

Colorfastness is a fabric's ability to resist fading from sun and washing. Fading is caused by UV rays breaking down the fabric's dyes, making a cover look old prematurely.

This is where solution-dyed fabrics excel.

- Traditional Dyeing: Color is applied to the surface of the finished fibers, making it susceptible to fading as UV rays break down the surface dye.

- Solution-Dyeing: Pigment is mixed into the liquid polymer before the fiber is created. The color is locked into the core of the fiber.

The result is a color that is inherently fade-resistant. Sunbrella® Acrylic is 100% solution-dyed, which is why its colors stay vibrant for years. This superior color retention indicates a high-quality fabric designed for long-term performance. Solution-dyed boat cover materials are a cornerstone of the premium covers we create.

Construction and Durability: The Unsung Heroes

Even the best boat cover materials fail without quality construction. The thread, stitching, and components like zippers are critical to a cover's durability. This is where craftsmanship makes a difference in custom marine covers.

Choosing the Right Thread and Stitching

In high-UV South Florida, the sewing thread is as important as the fabric. Standard thread degrades quickly under UV exposure, causing seams to fail long before the fabric does.

UV-resistant thread is essential for marine applications. While strong, standard polyester thread becomes brittle and breaks under UV exposure. We recommend high-quality, marine-grade polyester thread engineered for outdoor use.

For ultimate durability, lifetime PTFE thread (like Tenara®) is the gold standard. It's impervious to UV degradation, saltwater, and mildew, ensuring seams last as long as the fabric. Though costly, its longevity is a worthwhile investment for luxury yacht covers, and research confirms its value for high UV resistance.

Beyond the thread, the stitching process itself is crucial:

- Needle size: Heavy-duty boat cover materials require a large needle (#18 or larger) to prevent skipped stitches and create a strong seam.

- Heavy-duty sewing machines: Domestic machines often fail when sewing marine canvas. Professional heavy-duty sewing machines with metal gears and powerful motors are essential for penetrating thick fabric and creating durable seams.

- Seam strength: We use techniques like double stitching and felled seams to distribute stress and maximize strength.

Zippers also require careful selection. We prefer #10 plastic zippers for corrosion resistance and recommend covering them with a canvas flap to protect them from UV degradation.

For more insights into the construction of durable covers, you can explore our resources on Canvas Boat Covers. The combination of the right boat cover materials with expert stitching and components ensures a protective solution that truly endures.

Frequently Asked Questions about Boat Cover Materials

Choosing the right boat cover materials raises many questions. Here are answers to common inquiries from our South Florida clients.

How do climate and usage affect my choice of boat cover materials?

South Florida's climate of intense sun, high humidity, and heavy rain heavily influences the choice of boat cover materials.

- Sun Exposure: High UV makes superior resistance paramount. Solution-dyed acrylics (e.g., Sunbrella®) are the top choice for their 10-year longevity.

- Humidity and Saltwater: High humidity demands breathable fabrics or excellent ventilation for waterproof ones. Saltwater requires corrosion-resistant components like plastic zippers.

- Trailering Frequency: Trailering requires robust, chafe-resistant, and "trailerable" materials like Sunbrella® or Sun-DURA™ to withstand highway speeds.

- Storage Duration: Long-term outdoor storage requires a heavy-duty, UV-resistant, breathable material. For short-term use, a lighter material may be preferred for easier handling.

At American Marine, we consider these factors to design custom covers perfectly suited to your vessel's lifestyle.

What are common maintenance needs for different boat cover materials?

Proper maintenance extends the life of any boat cover. Different boat cover materials have varying needs:

- Cleaning: Clean all fabrics regularly to prevent mildew. Acrylics and polyesters clean well with mild soap and water. Non-porous PVC fabrics are very easy to wipe clean.

- Re-treating Water Repellency: Re-apply a water repellent like 303® Fabric Guard to water-resistant fabrics every few years to maintain performance.

- Mold Prevention: Proper ventilation is the best defense. Use support poles and vents for waterproof covers and ensure airflow for breathable ones.

- Patching Tears: Promptly patch small tears with repair tape or fabric to prevent them from growing.

- Zipper Care: Regularly clean and lubricate plastic zippers with a marine-grade product to prevent seizing. Keep them covered from UV.

How can I ensure proper ventilation under a waterproof cover?

Proper ventilation under waterproof boat cover materials is paramount in South Florida's humid climate to prevent mold, mildew, and condensation damage.

Here’s how to ensure adequate air circulation:

- Support Poles: Use support poles to create a "tent" shape. This prevents water from pooling and creates air pockets for circulation, stopping the cover from trapping moisture.

- Vents: Strategically placed, mesh-covered vents allow moist air to escape while keeping rain out. We integrate these into our custom covers.

- Proper Fit: A custom fit should be snug but not airtight. Our 3D-measured covers are designed to allow necessary air exchange.

- Air Circulation: You can also lift the cover's edges on dry days or use small dehumidifiers or fans underneath during long-term storage.

These strategies mitigate the main disadvantage of waterproof boat cover materials, providing comprehensive protection for your yacht.

Conclusion: Investing in the Right Protection

Choosing the right boat cover materials is a pivotal decision for your vessel's preservation. In South Florida, factors like intense UV, humidity, and saltwater influence which fabric offers the best defense. We've covered the differences between breathable acrylics, durable polyesters, and waterproof PVC, highlighting key factors like UV resistance, chafe protection, and colorfastness.

There is no single "best" material—only the best one for your specific needs. At American Marine, we specialize in custom covers for luxury yachts in South Florida, prioritizing materials with top-tier UV resistance, breathability, and durability. We match these elite boat cover materials with our 3D-measuring and precision-cutting to deliver protective, aesthetically pleasing solutions.

Here's a quick summary to help you weigh your options:

| Feature | Solution-Dyed Acrylic (e.g., Sunbrella®) | Marine-Grade Polyester (e.g., Sun-DURA™) | PVC-Coated/Vinyl (e.g., Stamoid™) |

|---|---|---|---|

| Pros | - Excellent UV resistance (10+ yrs) | - Good initial strength | - 100% Waterproof |

| - Superior breathability | - More dimensionally stable | - Very easy to clean | |

| - Excellent colorfastness (solution-dyed) | - More affordable than acrylic | - Heavy-duty, robust feel | |

| - Resists mold & mildew | - Good water repellency (coated) | - Good tear resistance | |

| Cons | - Higher cost | - Strength degrades faster (5-8 yrs) | - Non-breathable (high mold risk) |

| - Less chafe resistant than some polyesters | - Coatings may require re-treatment | - Heavier and bulkier | |

| - Can be more prone to shrinking/stretching | - Less UV resistant than acrylic | - Higher cost than polyester | |

| - Colors may fade over time (non-solution dyed) | |||

| Ideal Use | - Long-term storage | - General storage/mooring | - Bimini tops, specific waterproof needs |

| - High-UV environments (South Florida) | - Trailering covers | - Requires excellent ventilation | |

| - Premium custom covers | - Balanced performance/cost |

Investing in the right boat cover materials and a custom fit is an investment in your vessel's longevity and beauty. It means less worry about maintenance and more time enjoying the water.

We craft custom marine covers that offer unparalleled protection. Our 3D-measuring and precision-cutting process ensures a flawless fit using elite materials built for the harshest conditions.

Ready to protect your investment with a cover designed for excellence?